Layer by layer: the future of 3D printers

Imagine having the ability to create just about anything you want with the touch of a button; in years to come, 3D printing technology could provide us with precisely that.

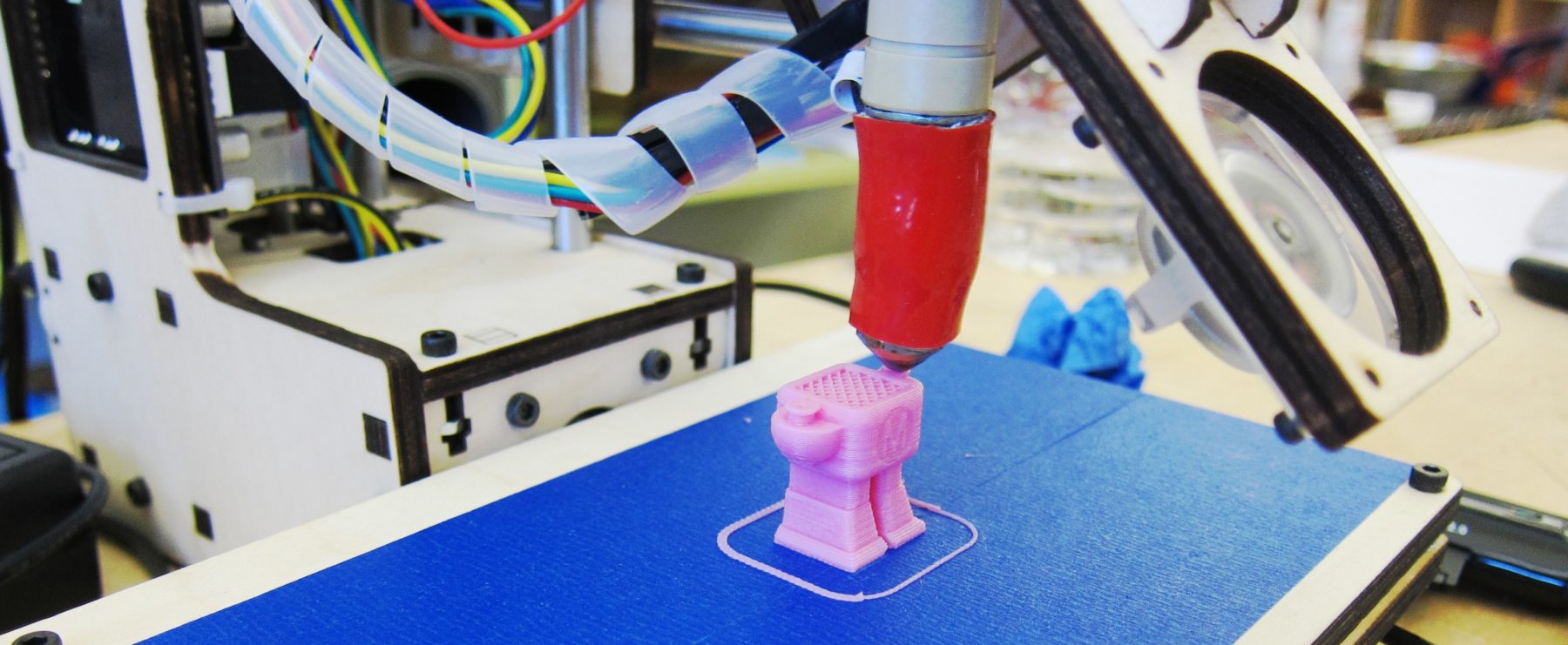

3D printers are completely different to the printers you use at home or at the library; conventional 2D printers print information, 3D printers build objects. Modelling software is used to digitally design an object (Computer Aided Design), and then individual cross-sections of that object are laid down as successive layers to gradually build the 3D structure – it’s an additive process. These layers are generally made up of either liquid or powder, and are fused together to form the final structure.

Food, biological tissue, cars, guns, textiles, rocket parts, digital hearing aids, household appliances and drones are all examples of 3D-printable objects, but it’s the medical and surgical fields which have had some of the most exciting developments. For instance, it has been shown that 3D printing can be used for chemical synthesis – reaction vessels were designed and printed, before a second printer cartridge released specific chemicals, which would react. This method could potentially be used as a way to print medicine.

The 3D printer has also shown promise in orthopaedic surgery, where a number of successful cases have used printed parts. Examples include a UK patient who had half of his pelvis removed to stop the spread of a rare bone tumour. The missing part of his pelvis was printed using titanium powder and implanted as part of the hip transplant surgery. In Belgium, a woman had a lower jaw transplant, also from printed titanium. This now allows her to eat, speak, and breathe normally. In March this year, the face of 29-year-old Stephen Power was re-built after he suffered severe facial disfigurement from a motorcycle accident in 2012. The eight-hour operation took place at Morriston Hospital in Swansea where the surgeons were able to correct the symmetry of his skull using 3D models based on CT scans. This allowed for great precision, taking away the problematic guesswork normally involved with reconstructive surgery.

China in particular is looking towards 3D printing as a way to overcome the problem of organ supply and demand: ears, livers and kidneys have all be made from a 3D bio-printer, which uses living cells instead of plastic to build tissue. While it is still early days, it is believed that in a decade or two these organs will be fully functioning and ready for use – eradicating the need for organ transplant lists.

Of course this technology also has a lot of novel applications; printed clothing has been modelled on the catwalk, and there’s already a market for printed lingerie and jewellery. There has even been interest from the sex toy industry – if you’re prepared to pay, it is currently possible to get a sex toy specifically tailored to personal body scans. Nothing says romance quite like the gift of a 3D-printed dildo modelled after your very own penis!

Printing under zero-gravity conditions is currently under development, prompting interest from NASA. If astronauts took a 3D printer into space, in principle they would be able to print virtually anything they needed: there would be no need to waste fuel and storage carrying basic items, spare parts, even food. A 3D printer cartridge can be filled with many things – NASA has commissioned a printer with multiple cartridges filled with long-life cheese, dough, and sauce materials. Pizza on tap? Yet another reason for all children to be aspiring astronauts.

While this technology has been around since the 1980s, it is only in recent years that it has become commercially viable. It is already possible to buy a basic 3D printer online for roughly £500, and the printer itself could even be used to self-replicate – a 3D printer can print 3D printers! It’s easy to see how this technology will spread, and 3D printers are expected to become household regulars. It seems that in the not-so-distant future, you could be printing your own coat hangers instead of buying them at a store, or perhaps design your own children’s toys.

Comments (2)

Amazing technology that opens the vast oceans of Manufacturing opportunities that was by few elites till now @ smartprinting.co